Visits: 1010

Freshwater sources are scarce in many parts of the world.

As demand for fresh water increases amid population growth and weather changes, people look towards natures greatest source of water i.e. the sea.

The use of Seawater Reverse Osmosis (SWRO) will continue to increase across the globe to satisfy the demand for fresh water.

SWRO currently accounts for more than two-thirds of the world's desalination needs.

What is SWRO Pretreatment?

Pretreatment of SWRO is an essential part of this desalination process. The main purpose is to remove as much particulates, microorganism and silts as possible before the reverse osmosis membranes. Effective pretreatment helps prolong membrane life by preventing or retarding RO membrane fouling process.

Types of Pretreatment

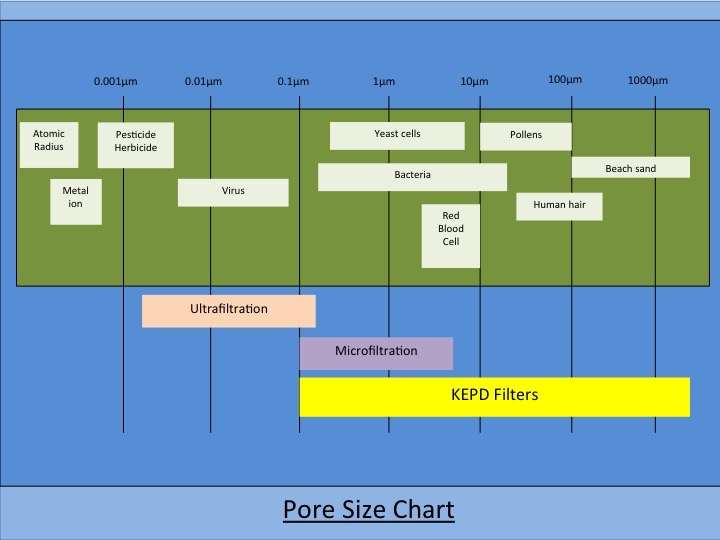

Currently conventional multi-media sand filters and membrane filtration are the most common pretreatment methods. Ultra- and Micro Filtration (UF/MF) are membrane pretreatment methods that are currently preferred over conventional filtration systems. UF/MF systems have broader spectrum of particle removal capabilities than conventional multi-media filters.

Failure of conventional multimedia sand filters

Conventional sand filters, while having a lower cost to manage are inefficient filters that are prone to failures due to inherent design shortcomings. Common issues with conventional sand filters include sand channeling and mud balling, bio fouling, sand loss and tank corrosion. One of the most common issues of conventional sand filters is corrosion of vessels.

Membrane pretreatment cost too high?

It is estimated that the cost of producing desalinated water using membrane pretreatment alone is much higher than plants that use conventional multi-media granular filters. Some of the overlooked factors that increases fresh water production cost using membrane methods are,

- heftier implementation cost and costs of maintaining the micro-screening system needed to protect the UF/MF;

- chemical costs and frequency of UF/MF cleaning and chemically enhanced backwash;

- actual operational life and replacement costs of UF/MF – most analyses assume about 60-70% of the expected lifespan of the UF/MF membranes due to overloading of the membranes as particles as large as 70 µm are being filtered out on pore sizes smaller than 0.1 µm.

KEPD for SWRO Pretreatment

KEPD Filtration Systems (KEPD) manage costs effectively

KEPD was developed to solve all the issues faced by conventional multi-media filters and is able to provide consistent water quality due to its unique design

KEPD closes the gap between conventional multi-media filters and UF/MF systems.

KEPD, with its unique features and its filtration efficiency of 0.1µm, outperformed conventional multi-media filters. In certain cases KEPD assumes the efficiency comparable to that of UF/MF membranes.

The lower implementation, operating and maintenance cost of KEPD positions itself as an ideal solution to manage the high costs of operating UF/MF pre-treatment for SWRO by reducing the load factors on the UF/MF membranes, and in certain scenarios even provide an alternative pretreatment system for SWRO.